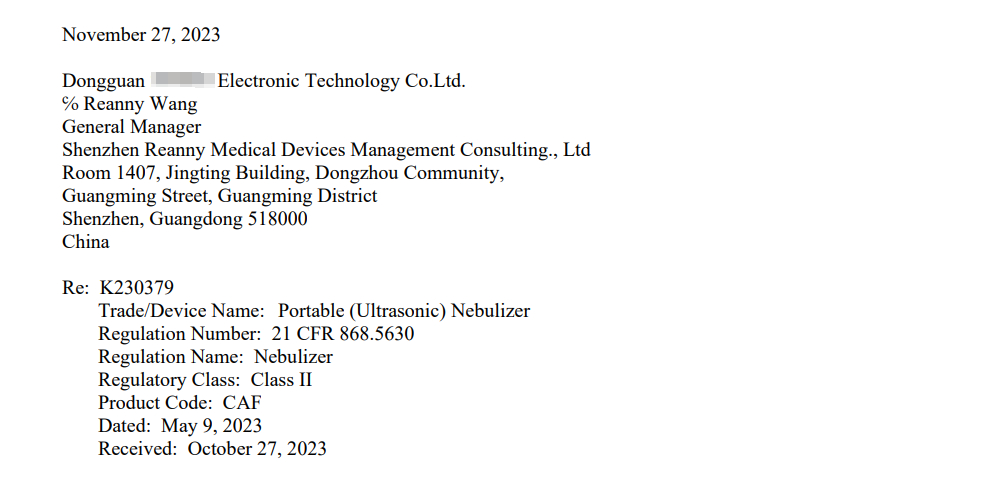

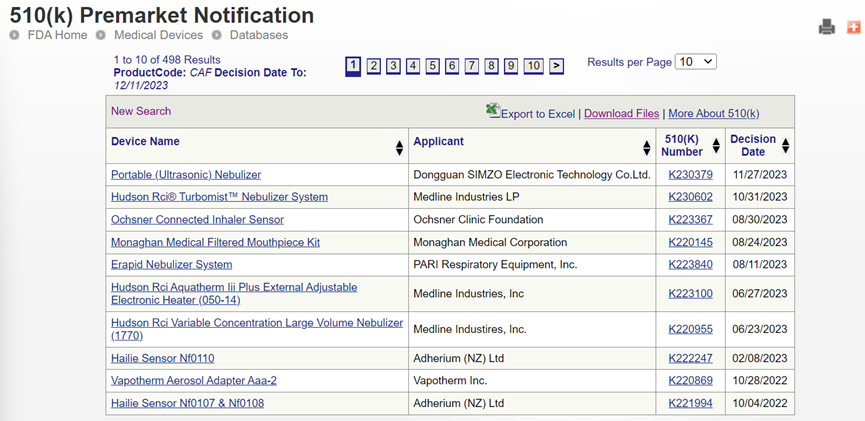

Rui Enni helps a company in Dongguan obtain FDA 510k registration for ultrasonic atomizer

In February 2023, Rui Enni submitted a 510 (k) application for an atomizer, and after efforts, it finally passed the FDA review at the end of November and obtained the US market qualification. In recent years, there have been very few records of nebulizers approved by the FDA. The entire respiratory therapy series of products has received special attention from the FDA, with very strict evaluation standards that make it difficult for consulting firms and manufacturers to handle.

Below is a brief sharing of the problems and experiences encountered during the application process.

1. Applicable standards for 510k:

|

Number |

Category |

Standard Number |

|

1 |

Electrical safety |

IEC 60601-1 |

|

2 |

Electromagnetic Compatibility |

IEC 60601-1-2 |

|

3 |

software |

IEC 62304 |

|

4 |

Household Electrical Safety |

IEC 60601-1-11 |

|

5 |

risk |

ISO 14971& ISO TR24971 |

|

6 |

Biocompatibility |

ISO 10993 series standards (depending on actual testing projects) |

|

7 |

Gas path biocompatibility |

ISO 18562-1/-2/-3 |

|

8 |

Cleaning/Disinfection |

FDA Medical Device Reprocessing Guidelines and Corresponding Standards |

|

9 |

Particle characteristics |

FDA Nebulizer Guidelines, United States Pharmacopeia |

|

10 |

performance standard |

ISO 27427 |

2. Biocompatibility requirements

Based on nebulizers, drugs are atomized and deposited into the respiratory tract or lungs through respiration. The biocompatibility of drug pathways such as medication cups, masks, and hoses is classified as permanent (>30 days) external access devices that come into contact with tissues. Therefore, its biocompatibility requirements are high, and in addition to the basic three items, more biocompatibility tests need to be conducted according to the requirements of Table A.1 of ISO 10993-1. Alternatively, chemical characterization and toxicological evaluation can be used instead of partial testing, such as chronic toxicity and genetic toxicity. Special attention should be paid to achieving exhaustive extraction in the testing of chemical characterization, and multiple standard substances should be selected for quantitative analysis in the analysis of organic compounds.

3. Biocompatibility requirements for respiratory pathways

The atomizer still has a gas pathway, so it needs to be tested according to the ISO 18562 series standards based on the actual situation. In the process of conducting these tests, the main issues are that the testing conditions and methods should be clear and complete, and the results should be as detailed as possible. For example, VOC testing should ensure that it reaches a stable state or is below the allowable intake, and the worst-case exposure within the expected lifespan should be considered during the testing process.

4. Characteristics of atomized particles

The aerosol performance testing of nebulizers is also a key focus of FDA attention. According to the FDA's guidelines for nebulizer evaluation, it should include at least three tests on the particle size distribution of nebulized drugs. The FDA approved atomization particle test is a multi-stage impact test method, which is different from the laser scattering method commonly used in our domestic testing. At present, there are few laboratories in China with testing equipment, methods, and experience in FDA approval, so the choice of laboratory is very important.

5. Lifespan characteristics

The impact of the lifespan of atomizers on atomized particles and their impact on cleaning and disinfection is also a concern for the FDA. In the past, it was easy for everyone to prove the product's compliance through verification after making a prototype. However, this approach often only proves that the product meets the corresponding validation requirements, but cannot prove that the product meets the corresponding validation requirements throughout its entire lifecycle.

Finally, to summarize, for some medical devices that receive high attention from the FDA, the FDA has very high requirements for testing reports. Choosing a laboratory with successful experience and rich technical experience will be very important. With the increasingly strict FDA review, the review has now shifted from product descriptive information and accuracy to verification and confirmation reports. So the era of having no problems as long as a laboratory report is obtained, as developed in domestic registration and CE registration, is over.

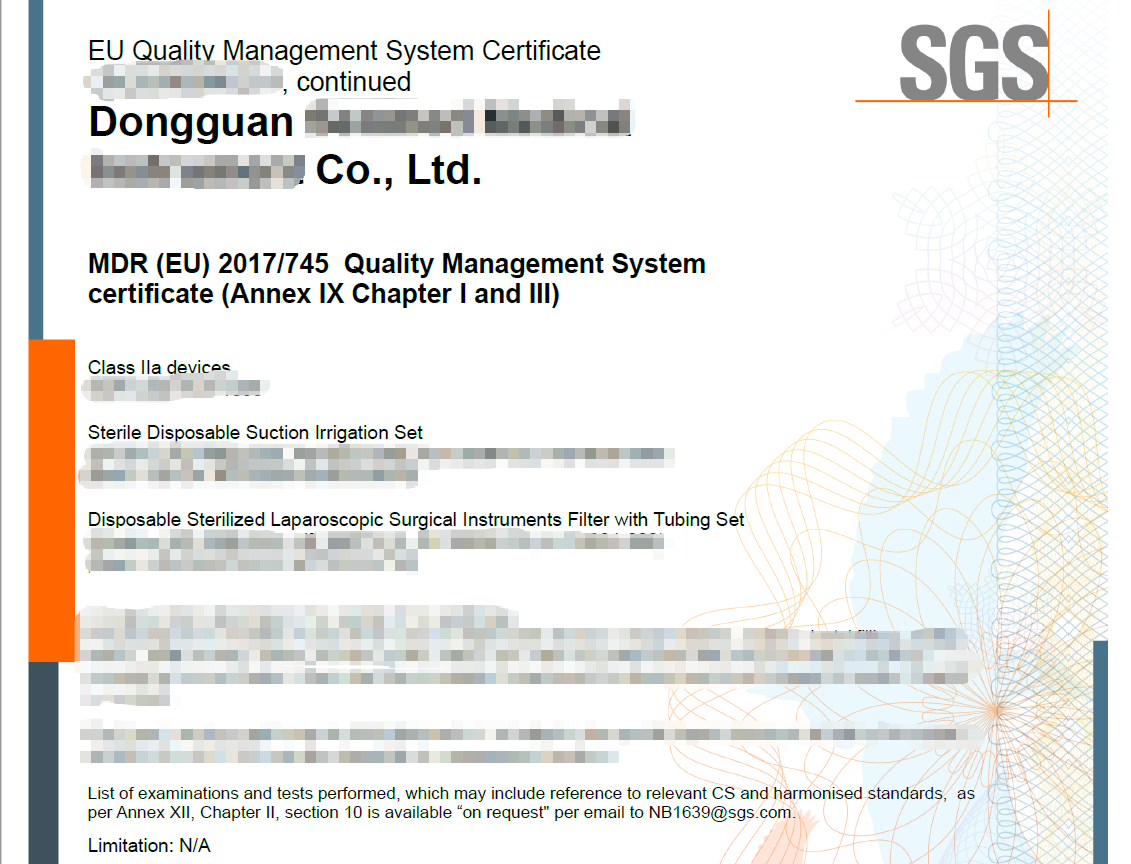

Similarly, choosing a consulting firm with experience in the same product is also a very important factor for the success of the project. Rui Enni Consulting has completed dozens of domestic, CE, and FDA projects for disposable atomizers, compression atomizers, ultrasonic atomizers, and mesh atomizers. I have accumulated rich practical experience in the characteristics of atomizers, and some consultants have also worked in companies in the atomizer industry. These experiences will help Ryan Ni better provide consulting services for atomizer companies.